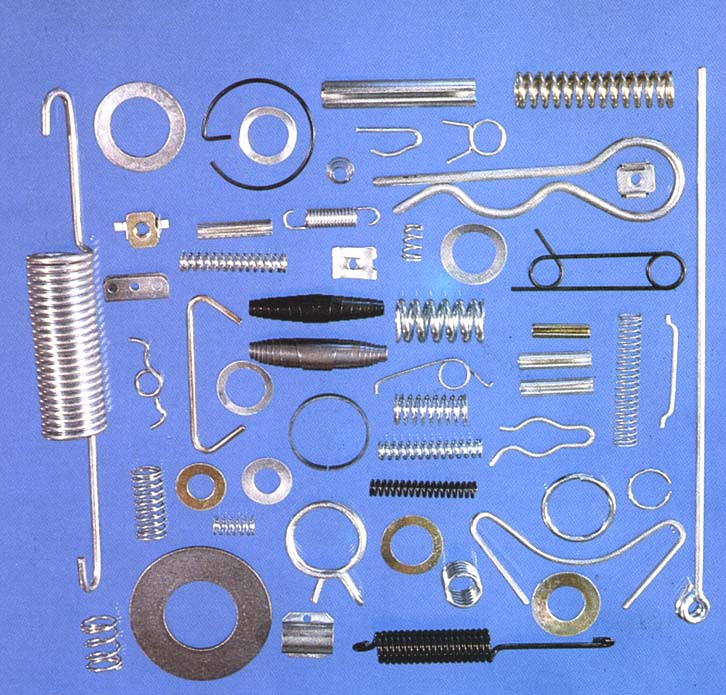

Wire forming parts, spiral spring, leaf spring

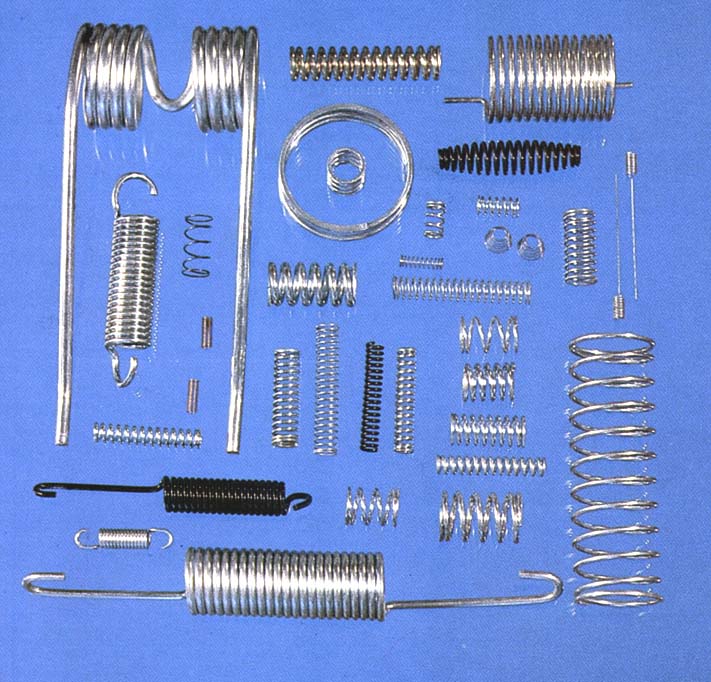

Precision extension- and compression springs, flat spiral springs.

Wire bending and forming parts to drawing and samples.

Materials:

Music wire to DIN 17223, Class C. No. 1.1200, BS 5216 ND 3 or HD 3, AMS 5112.

Stainless steel wire to DIN 17224, No. 1.4310, BS 2056 EN 58 A. Commercial 302 AMS 5688 spring temper.

Coiled:

Right hand or left hand to drawing or user specification.

Ends:

Wire up to 0,8 mm squared and unground. Wire over 1,0 mm squared and ground. Extensions springs German loops closed. End position will yary.

Loads:

Load values shown are for music wire and are based on a service life of 50 000 cycles at 0,50 stress range. For normal service springs should not be compressed below L1.

Tolerances:

All dimensions and forces to DIN 2095 / DIN 2097 (Grade 2).

Surface finish:

Normal wire oiled. Shot-peened and plated finishes supplied on request. Allow sufficient additional time for special finishes. To determine the load at any working length use rate x proposed deflection.

1 lb = 4,448 Newtons, 1 Newton = 0,225 lb.

For compression springs with a higher spring rate (P/f) see Heavy